Rugged Connectivity: Peak Performance no Matter the Environment

04/08/2024 //

Connector failure in rough conditions is something most of us don’t think about until it happens. But, as they say, an ounce of prevention is worth a pound of cure, so it's better to think about it before it happens. Whether you're building factory robotics, aerospace equipment, or devices intended to work undersea, you need to ensure that your products are made to withstand extreme pressure, temperature variations, rough handling and anything else the environment might throw at them.

When Harsh Conditions are Part of the Job

For many, rough conditions are just part of the job, not merely something you need to worry about for a few weeks every winter or only when driving through gravel and swamp lands. Power fluctuations, excess moisture, chemical exposure and even salty air constantly threaten those who rely on their equipment to get the job done in less-than-ideal conditions.

The most obvious examples of harsh conditions are natural environments – underwater, off- highway, space, etc. – where physical material considerations come into play. For instance, insulation tends to be less effective at higher altitudes, meaning that equipment used in aircraft of all types, including eVTOL and spacecraft, will need to be built from the ground up to prevent flashover, wherein tightly clustered electronics ignite as a result of the shared heat they're generating.

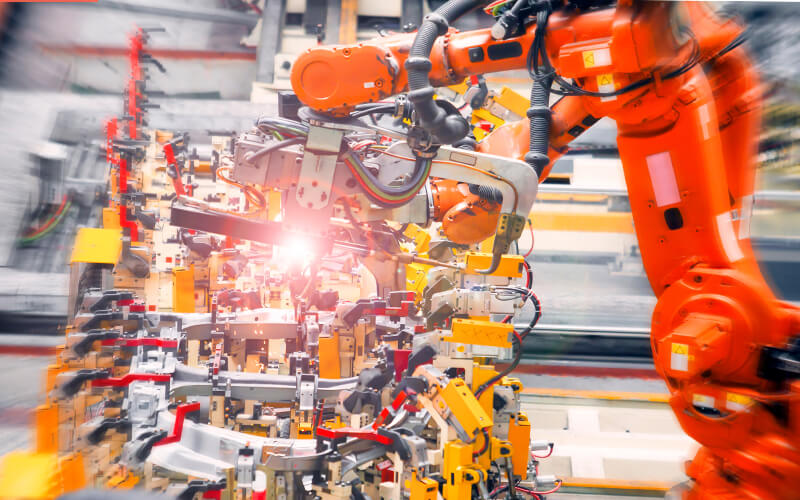

But even in a totally controlled environment, like a factory floor, automated equipment and robotics have to contend with dust, machining oil, moisture and possibly shock from constant use, moving heavy objects from point A to point B, and the extreme temperature variations that often come with the job.

Is Your Equipment Built to Last?

Developing equipment that can withstand these conditions is a constant process of testing and improvement. Innovations occur daily in insulation, corrosion resistance, sealing and pressure shielding for work below the sea level and above the stratosphere.

Managing these concerns and building electronic equipment you can count on in uncertain conditions is a trying task at any level. Doing it at scale is another matter entirely, and that’s only compounded when you have to do it within a specific budget and time frame. And, of course, you must deliver all that without compromising functionality. Insulation and impact resistance at the cost of weight and portability only introduce new problems.

A guiding principle in developing equipment for extreme conditions is to forget the one-size-fits-all solution and to source, design, and build equipment around the specific hazards relevant to your field of operation. When building electronics for a harsh environment, a "trial and error" approach to finding the right components quickly gets very expensive.

This is why TTI takes pride in guiding our partners to the best technology available for their needs, sourcing connectors built specifically for harsh environments. We bring decades of combined experience to the table to deliver exactly what you need, no matter where the journey takes you.

Steve Brahosky

Steve Brahosky, business development manager with TTI, Inc, has over three decades of experience in the electronic components industry. He specializes in connector technology and has worked with customers on the technology that enables electrification and other innovations across a wide range of industries.